Cement industry

Atashgah Steel Company's strong presence in the cement industry

As one of the main suppliers of wear-resistant and heat-resistant parts in the cement industry, Atashgah Steel Company offers innovative solutions to increase productivity and reduce maintenance costs of cement equipment by utilizing advanced technologies in production, heat treatment and materials engineering.

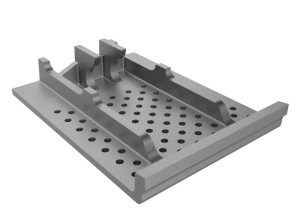

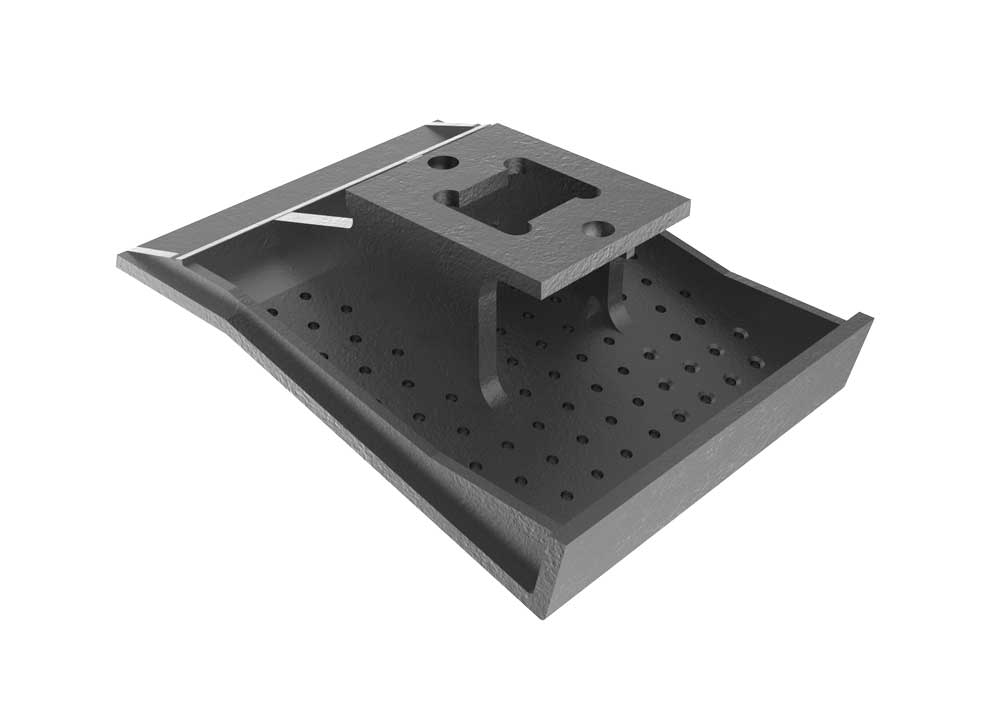

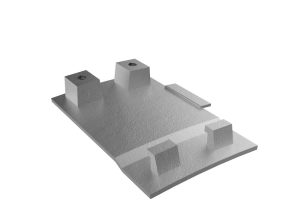

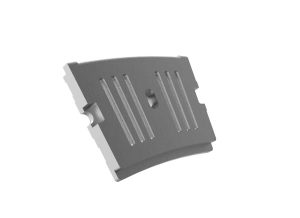

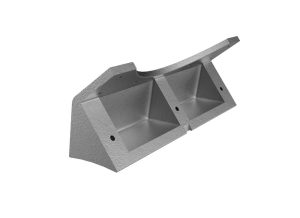

Focusing on key sectors of the cement industry, the company produces a wide range of wear-resistant and heat-resistant parts. In the stone crusher sector, the production of rock crusher hammers, various types of rock crusher body armor and other related parts produced by this company, using resistant alloys, has increased the life of the equipment and reduced maintenance costs. In the grinding of materials and cement, the production of various types of grinding chamber diaphragms and various types of grinding body liners (armor) using engineered compounds helps to improve performance and increase process efficiency. Also, in the cement kiln unit, the production of various grate coolers, silicone flaps, sigments, immersion tubes used in kilns and other required parts, taking into account the harsh working conditions, guarantees the durability and optimal performance of the equipment.

In equipment such as internal parts of the mill that are subject to severe wear, cast parts must have the highest abrasion resistance. Meanwhile, in addition to wear, they must also be resistant to dynamic stresses that can lead to sudden failures. The chemical composition of alloys and subsequent heat treatment play a key role in optimizing the abrasion resistance and toughness of these parts. The elements carbon and chromium are among the most important factors affecting the simultaneous increase in abrasion resistance and toughness in iron alloys. By precisely adjusting their percentage, the optimal performance of the parts is guaranteed. The properties mentioned in the parts used in cement kiln departments depend on observing the ratio of the two main elements chromium and nickel. In order to further improve the aforementioned properties, this company also uses the addition of elements such as molybdenum and niobium, etc.

Another service of this company to the cement industry is the production of cast iron balls used in this industry. This product, which is produced by the casting method in this company, is provided to the cement industry in various sizes and chemical analyses with the characteristics of high abrasion resistance; resistance to fracture and deformation, and maintaining a spherical shape during the process.

- Advanced heat treatment furnaces

- Specialized laboratories for mechanical and metallurgical properties

- Material analysis and optimization to increase component life

- Use of high-chromium (Hi-Cr) and Ni-Hard cast irons

- Increase useful life and reduce wear

- Improve material crushing efficiency in mills

- Manufactured from heat and corrosion resistant alloys

- Excellent resistance to harsh cement kiln conditions

- Increases durability and reduces maintenance costs

- Use of manganese steels and wear-resistant alloy cast irons

- Increase hardness and improve impact resistance

- Custom design to suit working conditions

- Made of high-strength alloy steel

- Precise heat treatment to increase service life

- Resistance to high temperatures and mechanical stresses

- By using modern casting and heat treatment methods

- Production of cast iron balls with high abrasion resistance, resistance to fracture and deformation, and maintaining spherical shape during the grinding process

- Production in various sizes and chemical analyses

Benefits of cooperation with Atashgah Steel Company

The use of resistant alloys and precise heat treatment reduces component wear and increases equipment productivity.

Using parts with high hardness and strength reduces downtime due to breakdowns and increases production efficiency.

All products are produced and controlled under strict international standards.

Using a specialized engineering team, components are designed and manufactured according to each customer’s specific operating conditions.

Download catalog

Do you have any questions? Contact us!

Sepahan Foolad Atashgah Casting Industries Company, with over 30 years of experience in the casting industry, is committed to self-sufficiency by leveraging skilled personnel and experienced managers. The company proudly serves various industries, including steel, copper, mining, cement, and their related sectors, as well as producing cast iron balls required by different industries.

Address

Isfahan – Najafabad – Najafabad Industrial Park 2 – Sanat Square – Doctor Hesabi Blvd – Sub-corner 28