Heat treatment

Heat Treatment

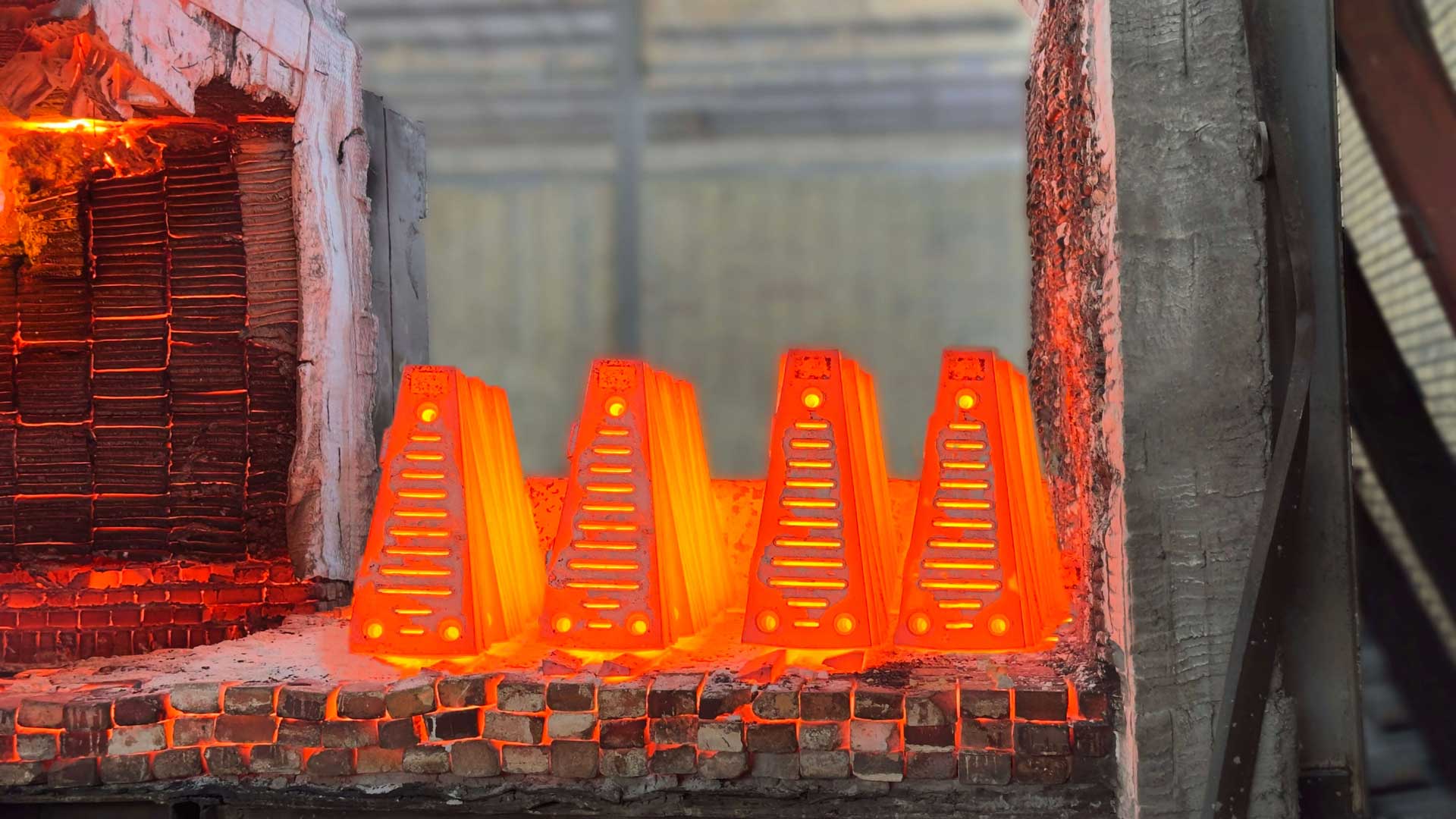

Atashgah Steel Company, utilizing two separate halls for heat treatment, has the ability to perform a variety of heat treatment processes on its produced alloys. These processes are carried out in two main categories: heavy furnaces and semi-heavy and light furnaces, enabling heat treatment on parts ranging from small to large and extra-heavy sizes.

Each alloy requires specific heat treatment processes depending on its chemical structure and industrial application. The following table shows the specific heat treatment processes for each alloy:

| Alloy Group | Heat Treatment Process | Description of Operation |

| Ni-Hard Cast Iron | 1. Preheating | 2. Austenitizing | 3. Air Quenching | 4. Tempering | Increase hardness, wear resistance, and toughness |

| Ductile Cast Iron (Malleable) | 1. Annealing | 2. Normalizing | 3. Quenching and Tempering | Optimize mechanical properties and increase strength |

| High Chromium Cast Iron (Hi-Cr) | 1. Homogenization | 2. Austenitizing | 3. Air Quenching | Increase wear and corrosion resistance |

| Manganese Steels (Hadfield) | 1. High temperature solution treatment | 2. Rapid water quenching | Increase toughness and impact resistance |

| High Carbon and Low-Alloy Steels | 1. Normalizing | 2. Surface hardening | 3. Quenching and Tempering | Increase surface hardness and mechanical strength |

| Austenitic and Martensitic Wear-Resistant Steels | 1. Austenitizing | 2. Air Quenching | 3. Tempering | Increase wear resistance and optimize toughness |

| Tool Steels | 1. Preheating | 2. Austenitizing | 3. Air Quenching | 4. Tempering | Increase hardness and fatigue resistance |

| Stainless Steels | 1. Annealing | 2. Solution hardening | 3. Tempering or Nitriding | Improve corrosion resistance and mechanical properties |

- Heavy furnaces: For operations on large and heavy parts such as mill liners, industrial gears, and mining equipment

- Semi-heavy and light furnaces: Suitable for operations on smaller parts such as crusher hammers, anti-wear parts, and precision engineering parts

- Use of temperature control and data recording systems: All processes are carried out under precise temperature and timing control to ensure optimal mechanical properties.

- Increase the service life of parts by optimizing hardness and strength

- Reduce maintenance costs in mining, steel, cement and copper industries

- Improve resistance to wear, impact and corrosion

- Ability to implement custom cycles according to customer needs

Atashgah Steel Company, utilizing its technical knowledge and advanced equipment, is ready to provide heat treatment services to various industries including steel, mining, cement, copper industries, etc.

Unique Features of the Company's Heat Treatment Operations

All of the company’s produced materials are heat treatable.

Due to the extensive equipment and technical expertise, there are no limitations in performing heat treatment on various alloys

Download Catalog

Do you have any questions? Contact us!

Sepahan Foolad Atashgah Casting Industries Company, with over 30 years of experience in the casting industry, is committed to self-sufficiency by leveraging skilled personnel and experienced managers. The company proudly serves various industries, including steel, copper, mining, cement, and their related sectors, as well as producing cast iron balls required by different industries.

Quick Access

Address

Isfahan – Najafabad – Najafabad Industrial Park 2 – Sanat Square – Doctor Hesabi Blvd – Sub-corner 28