Production materials

Production materials

Heat-resistant steels are alloys that retain mechanical strength and chemical stability at high temperatures.

01

The applications of manganese steel are primarily focused on industries that require materials with high durability and the ability to withstand heavy loads.

02

The main application of high-chromium steels is in industries where material crushing processes are a core part of their operations.

03

Carbon steels are a group of steels with a chemical composition primarily consisting of iron and carbon, offering a variety of mechanical properties

04

Ductile iron, also known as nodular cast iron or spheroidal graphite cast iron, is one of the advanced and versatile types of cast iron

05

Ni-Hard and Ni-Resist cast irons are both specialized types of white cast iron, engineered for specific, high-performance applications.

06

Nickel-Chromium cast irons excel in specific industries such as mining equipment, cement, and material processing.

07

Gray cast iron is one of the most common types of cast iron, which has a gray appearance due to the presence of flake graphite in its structure.

08

Our Products

Products of Atashgah Steel Casting Company

01

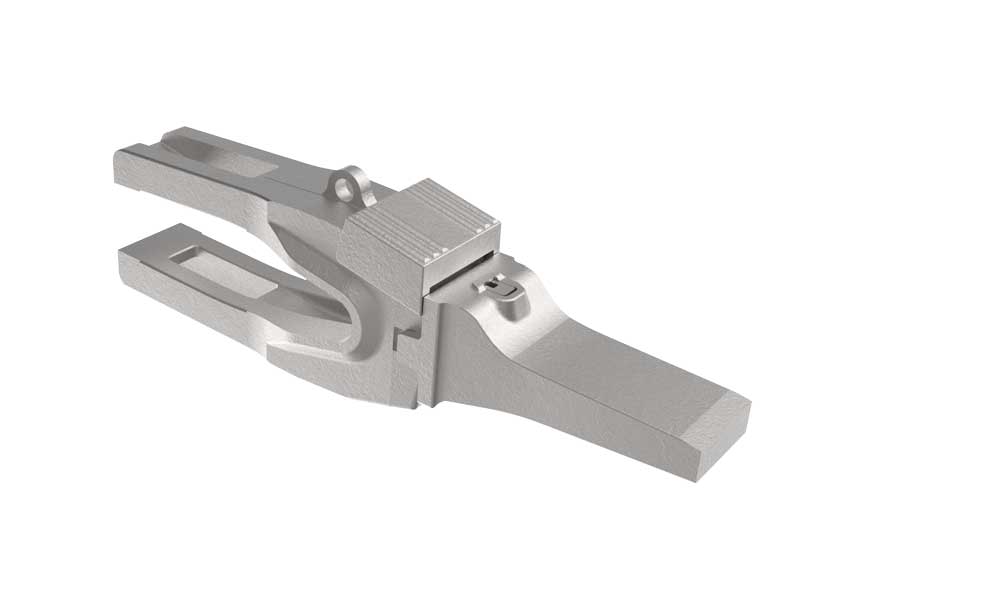

Mining Industry

A leader in the production and lifespan enhancement of AG & SAG mill liners.

02

Steel Industry

Specialized in casting parts for Pelletizing using Grate Kiln and Traveling Grate methods.

03

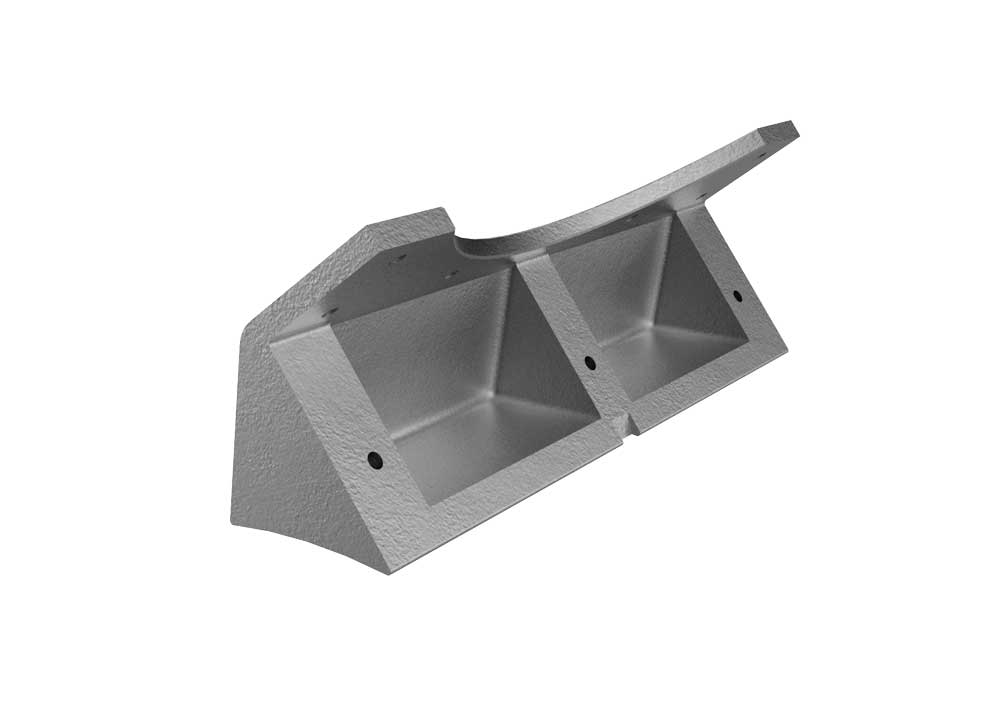

Cement Industry

Specialized production of all parts required for cement production departments

04

Copper Industry

Production of copper converter hoods, mouthpieces, and ball mill liners with enhanced durability and lifespan.

05

Cast Grinding Balls

Specialized production of cast iron grinding balls for various industries with optimized performance.

06

Heat Treatment

Capable of performing various heat treatment processes on all produced alloys.

Production Stages

Production Stages of Parts

Work Process

01

Step

Design

Preparation of Technical Drawings for Parts Using Specialized Software

02

Step

Casting Simulation

Analysis of Molten Flow and Solidification of Parts to Reduce Defects

03

Step

Modeling

Creating Initial Models for Precise and Standardized Molding

05

Step

Melting and Casting

Transferring Molten Materials into Molds for Shaping Parts

07

Step

Finishing Operations

Final Polishing and Removal of Excess Material for Flawless Part Delivery

04

Step

Molding and assembly

Preparation and Assembly of Various Mold Components for High-Precision Part Production

06

Step

Heat Treatment

Improving the Mechanical Properties and Strength of Parts

08

Step

Packaging

Preparing Parts for Delivery to the Customer

Do you have any questions? Contact us.

Sepahan Foolad Atashgah Casting Industries Company, with over 30 years of experience in the casting industry, is committed to self-sufficiency by leveraging skilled personnel and experienced managers. The company proudly serves various industries, including steel, copper, mining, cement, and their related sectors, as well as producing cast iron balls required by different industries.

Address

Isfahan – Najafabad – Najafabad Industrial Park 2 – Sanat Square – Doctor Hesabi Blvd – Sub-corner 28

© 2024Designed and Developed by moroorgaran.