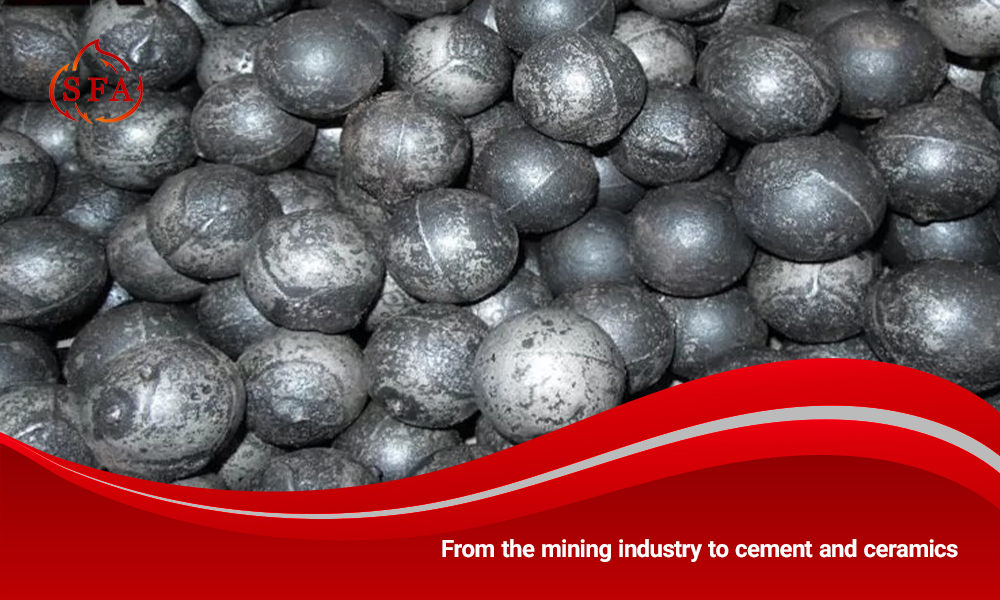

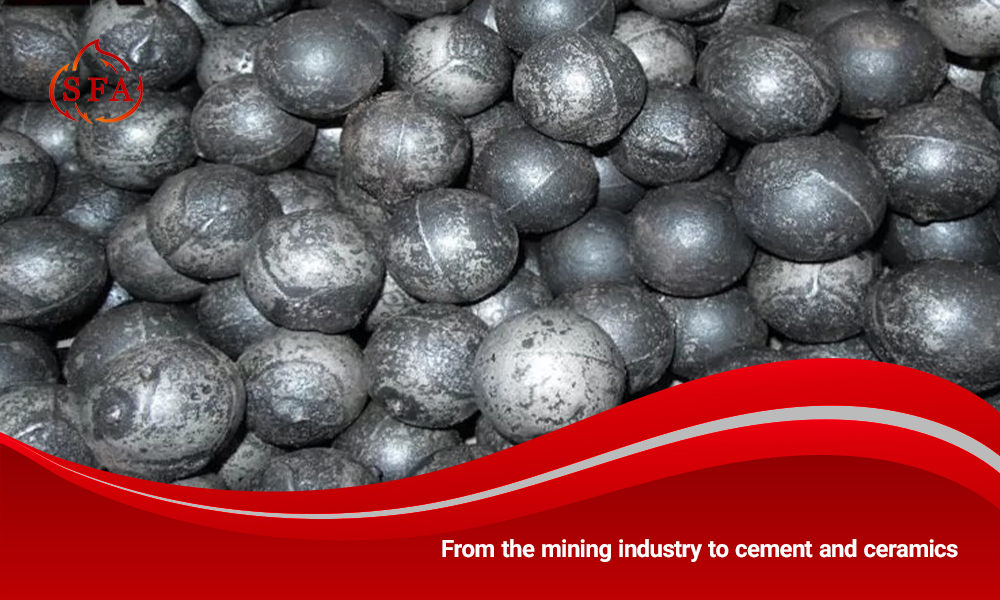

Steel grinding balls and their importance in various industries

Steel grinding balls, also known as spherical grinding media, are used in various industries to grind and pulverize materials. These balls play a very important role in the mining, cement, chemical and power industries by reducing particle size and facilitating extraction processes. In other words, steel grinding balls are one of the most important components of ball milling processes by improving grinding efficiency and uniformity of the final product. Industries widely use these balls in ball mills and semi-automatic grinding mills (SAG mills) to grind raw materials.

Raw material composition and technical characteristics of steel grinding balls

Manufacturers produce steel grinding balls from medium to high carbon steels and add controlled amounts of alloying elements such as manganese, silicon, and chromium. Typical ranges are 0.6–1.1% carbon, 0.5–1.2% manganese, 0.2–1.2% chromium, and 0.15–0.40% silicon. This composition, combined with precise heat treatments, balances hardness and toughness, providing excellent impact resistance.

Steel grinding balls have a high density (about 7.8–7.85 g/cm³) and hardness typically between HRC 55–65. Their hardness helps maintain shape and stability under repeated impacts, while impact resistance usually exceeds 12 joules per square centimeter. The high density applies greater force to the mill, enhancing grinding efficiency.

Click to read the article «The Best Grinding Balls for High-Impact Mills».

Production process: from casting to heat treatment

- Formation process: Depending on the type of media, there are two main methods:

- The main steps in the production of steel grinding balls include the following:

- Casting: In this method, molten steel is poured into spherical molds and shaped after cooling. The resulting balls are subjected to heat treatment (quenching and tempering) after formation to improve their hardness and structural integrity

- Selection of raw materials: In this step, raw steel with precise chemical composition is selected. The quality of the initial steel plays a key role in determining the final mechanical properties of the balls

- Forging: In this method, heated steel sections are shaped into spherical shapes by pressing or hammering. This process aligns the grain structure and increases the hardness and durability of the forged balls. After forging, technicians machine the balls and apply heat treatment to achieve the desired hardness and toughness. During final quality inspection, they check the dimensions, hardness, and impact resistance to ensure the balls meet international standards.

Applications: From the mining industry to cement and ceramics

Steel grinding balls have a wide range of applications in various industries, some of the most important of which are:

- In the mining industry, operators use these balls in ball mills to pulverize ore and extract valuable elements.

- Cement industry: In cement production, steel balls are used to grind cement clinker into a very fine powder. This process is crucial in achieving the desired grain size and mechanical properties of the final cement.

- In ceramics and related industries, manufacturers use steel balls to grind and mix raw materials and homogenize particle size in the production of ceramics, glass, and other industrial materials.

Advantages and disadvantages of steel grinding balls compared to other types

Among the advantages of steel grinding balls over other media, the following can be mentioned:

- High hardness and strength: These balls (especially the forged type) have high hardness (~HRC 60–65) and significant impact resistance, so they provide very effective performance in grinding hard materials.

- High density: The density of about 7.8 g/cm3 of these spheres allows them to produce much greater impact force and increase the efficiency of the mill.

- Economical: The initial cost of steel balls is lower than ceramic balls, and in addition, they have good wear resistance, which increases their operational life.

- At the same time, the following disadvantages are also relevant for steel balls:

- Corrosion and metal contamination: In humid or acidic environments, steel balls may undergo oxidation. Also, the presence of iron in these media can lead to the release of iron ions in the milled product, which is undesirable in some sensitive industries (such as pharmaceutical or food industries).

- Faster wear than ceramics: In applications with severe abrasion, steel balls wear faster than ceramic types and require frequent replacement.

Key points in choosing the right type based on application

The correct selection of steel grinding balls for a given application depends on several factors, the most important of which are:

- Nature of the target material: If the grinding process involves a sensitive product that should not have metal contamination (such as in the pharmaceutical or food industries), it may be more appropriate to use non-metallic or coated media. In mining and industrial applications where contamination is not a concern, steel balls are a good choice.

- Initial and final particle size: The size of the grinding balls should be proportional to the particle size of the input material and the final desired particle size. For example, larger particles require larger balls for primary grinding, while smaller balls are more effective for achieving very fine particle size.

- Density and hardness: The grinding media should be denser than the target material to prevent flotation in the mixture. The balls must have enough hardness to overcome the hardness of the material being ground. The harder the balls, the higher the grinding efficiency and the longer the media life; however, too much hardness may damage the mill body.

- Environmental conditions can affect steel balls. In corrosive or very humid environments, they may corrode, so industries use special corrosion-resistant alloys or coated balls.

- Cost and useful life: Steel balls have a lower purchase cost but require early replacement due to their relatively high wear rate. In contrast, ceramic balls are more expensive but have a longer life. Operators must weigh initial cost against operational life.

Globally recognized brands and manufacturers in this field

The following are among the leading companies in the production of steel grinding balls in the world:

Some of the leading manufacturers of steel grinding balls include Zhengxing Grinding Ball from China and EVRAZ from Russia. Moly-Cop, based in the USA and Australia, and Gerdau from Brazil are also major players. Other notable companies are Jinchi Steel Ball (China), GSI Lucchini (Italy), Magotteaux (Belgium), and AIA Engineering (India).

These companies have a significant share of the global steel grinding ball market with advanced technologies and strict quality control.

Direct purchase of steel grinding balls from Sepahan Foolad Atashgah

Directly purchasing steel grinding balls from Sepahan Foolad Atashgah offers an ideal solution for mining, cement, and ceramic industries seeking higher productivity and lower operating costs. Using high-quality steel balls optimizes the crushing and grinding process, extends equipment life, and improves product uniformity. Buying directly also eliminates intermediaries and provides access to products with international standards, controlled chemical composition, and precise heat treatment.

One of the key advantages of buying from this company is the possibility of benefiting from specialized advice from technical experts who help the buyer choose the best size and type of steel ball based on the type of material, environmental conditions and grinding purpose. This increases the efficiency of the mill and reduces the wear rate of the balls. In addition, the competitive price and the possibility of direct purchase eliminate the additional costs of intermediary suppliers and provide high economic value for industries.

As a result, buying steel grinding balls from Sepahan Foolad Atashgah not only ensures the quality and optimal performance of the mill, but also, with technical support and reasonable price, is a smart choice for industrial managers. This path allows industries to gain the most economic benefit from their grinding processes by reducing equipment failure, improving productivity and increasing the life of the media. For more information and a quote, you can contact our colleagues in the group as well as the commercial manager.

Final Conclusion

Steel grinding balls, with their superior mechanical properties, are of particular importance in optimizing grinding processes. Heavy industries such as mining and cement use these balls to increase grinding efficiency, improve cutting accuracy, and enhance product quality. Selecting the right chemical composition and production process ensures longer life and stable performance of steel balls. Overall, steel grinding balls remain a top choice for heavy-duty applications due to their high hardness, durability, and cost-effectiveness.