Why High Chrome Grinding Balls Are Essential for Cement Mills

In the cement industry, effective grinding of raw materials like limestone and silica ensures a uniform powder.

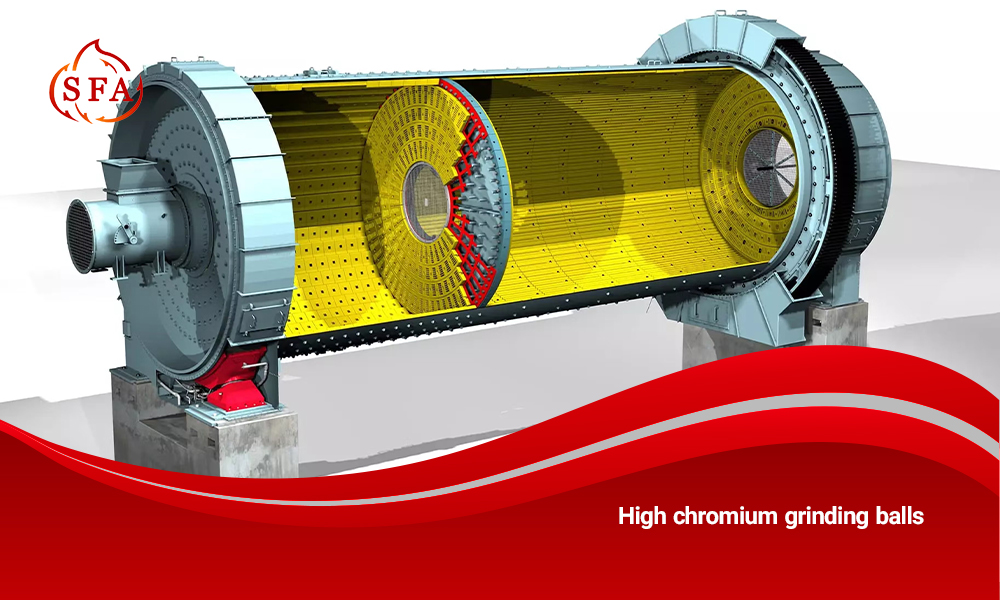

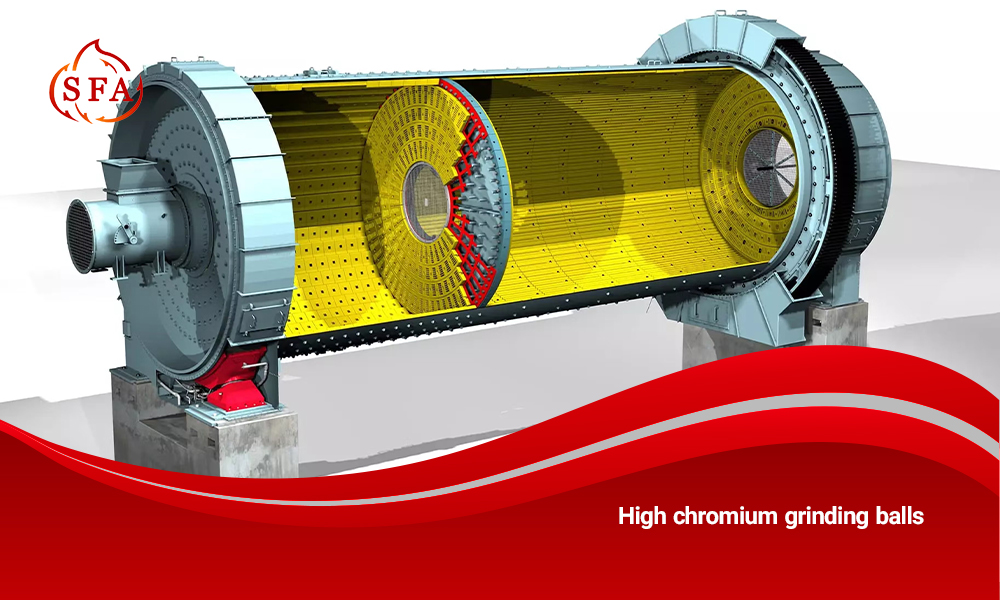

Grinding balls are key components in ball mills that crush rock through rotation and impact.

Cement manufacturers use high-chromium grinding balls as advanced media to resist hardness and severe abrasion during grinding. These balls have very high hardness and abrasion resistance with their special alloy composition and martensitic structure containing chromium carbides.

As a result, they last longer than ordinary balls and require less frequent replacement. With over 30 years of experience in industrial casting, Sepahan Foolad Atashgah is a leading manufacturer of high-chromium grinding balls. It also provides world-class quality products using modern casting and heat treatment technologies. In the rest of this article from Sepahan Foolad Atashgah, we will discuss the technical advantages of these pellets, their role in optimizing the cement grinding process, comparison with alternative pellets, impact on cement quality, and finally, conclusions.

Technical advantages of High chromium grinding balls

High structure and hardness:

Manufacturers use white cast iron or steel alloys with over 10% chromium to produce high-chromium balls. This special structure creates a high hardness (typically above 60–64 HRC). For example, high-chromium white cast iron has primary and secondary chromium carbides that are much harder than regular iron carbide and provide excellent wear resistance.

Wear resistance and long life:

The high chromium content, in addition to hardness, forms a resistant layer on the ball surface that significantly reduces the wear rate. This feature means that the need to replace balls over time is reduced and the mill’s productivity is increased. Research has shown that the use of high-chromium alloy balls reduces the wear rate to less than one-third of traditional (forged) steel balls. In fact, less ball consumption means lower operating costs and increased mill uptime.

Click to read the article «How to Buy Grinding Balls at Competitive Prices».

Non-deformation and shape retention:

High-chromium grinding balls are very hard and tough, resisting cracks from repeated impacts inside the mill.

Advanced design and heat treatment help these balls maintain their spherical shape during grinding.

Maintaining the balls’ spherical shape increases grinding efficiency and prevents issues like jamming and stress concentration.

Manufacturers produce high-chromium balls in various sizes (a few millimeters to over 100 millimeters) and chemical compositions for different applications.

This variety allows for the selection of balls to suit the conditions of each mill. In cement mills, operators typically use larger balls with lower hardness (about 60–62 HRC) in the initial grinding stages for larger particles, and smaller, harder balls (62–64 HRC) in later stages to achieve uniform grinding.

Advanced manufacturing technologies (including precision casting and electric arc furnace heat treatment) have also added to these benefits. The use of controlled heat treatment at Sepahan Foolad Atashgah has increased the mechanical hardness of High chromium grinding balls and reduced their wear rate.

In general, the outstanding technical properties of High chromium grinding balls (similar to those mentioned in high chromium cast irons) make them perform very efficiently in heavy abrasive and erosive environments, such as cement grinding.

The role of high chromium balls in cement mill optimization

Increased mill efficiency: By using high-chromium grinding balls, a greater percentage of the mill’s energy is spent on useful grinding of materials. The high hardness and uniform strength of these balls allow materials to be ground more efficiently and produce a larger volume of powder with the desired size. In other words, high-chromium balls make the grinding process more stable and increase the speed of cement powder production.

Using High chromium grinding balls to save energy

Since high-chromium balls have a much lower wear rate, the need for frequent replacement is reduced, resulting in less downtime for ball replacement. In addition to reducing maintenance costs, this also reduces energy consumption, as frequent changes inside the mill and reloading new balls usually involve higher energy consumption.

Reducing operating costs

The low wear rate of high chromium balls saves money. Research has reported that the use of high chromium balls not only significantly reduces the wear rate, but also minimizes the replacement of balls due to their long life. According to the report of Yazd Metal Smelting Company, the wear rate of these types of balls in the cement industry is very low and in addition to being used in gray cement mills, they are also used in white cement mills. In other words, the cost per ton of material ground with these balls is much lower.

Grinding process stability with High chromium grinding balls

High chromium grinding balls increase production stability by maintaining optimal grinding conditions (uniform particles, optimal mixing speed). Analyses show that improvements in pulp chemistry (mixture of water and ground material) and reduced additive dosage (in mining industries) have been side effects of using these balls; in the cement industry, such process optimizations also lead to reduced quality fluctuations and increased overall plant performance. In short, the use of High chromium grinding balls in cement mills leads to a more optimized grinding process. These balls increase operational efficiency and significantly reduce production costs by increasing service life and reducing maintenance downtime.

Comparative study with other bullets

Low-alloy white cast iron:

Low-chromium white cast iron balls (typically 0.5–1.5% Cr) have a structure consisting of cementite (iron carbide) and martensite phases. The hardness of these balls is typically around 58–62 HRC. These types of balls are used for softer materials or common mining industries such as copper and iron mines, but they perform less well in the severe wear conditions of cement mills.

High-Chromium White Cast Iron:

As mentioned, these balls have a much higher chromium content and form a structure of chromium carbides with martensite. This structural combination makes their hardness and wear resistance (about 60–64 HRC) much higher than low-alloy balls. As a result, the main use of high-chromium balls is in the cement industry, where the coarse grain size of the crushed raw materials requires high resistance. As stated in the description of the Yazd Metal Smelting Company, the main use of these balls is in the cement industry and the wear rate of these types of balls in the cement industry is very low.

Forged steel balls:

These balls are produced from alloy steel (such as 70Cr2) by forging and immediately quenched after forging to achieve the required hardness (~60–62 HRC).

Forged steel balls have very high toughness and impact resistance and are less likely to break. In contrast, their hardness is slightly lower than that of high-chromium balls. Based on a comparative study, forged balls are more resistant to severe impacts and temperature changes, but their wear rate in abrasive applications such as cement grinding is higher than that of high-chromium balls.

In other words, forged steel balls have a higher impact life but offer lower wear resistance than high-chromium balls.

Other grinding media (ceramic and polymer):

In some specific applications, ceramic balls (e.g. alumina) or polymer coatings are used. These options greatly reduce metal contamination, but their high manufacturing cost and greater brittleness (especially ceramics) prevent their widespread use in cement grinding. Therefore, in the cement industry, the main option is practically a heavy steel or cast iron composition, which has the highest durability.

Supply of castings and mill balls with Sepahan Foolad Atashgah

Sepahan Foolad Atashgah Company is one of the pioneers in the production of castings and grinding balls, especially High chromium grinding balls, in Iran, which has gained a special place in the cement, steel and mining industries with more than three decades of experience. This complex, by utilizing advanced casting technologies, precise heat treatment and strict quality control, offers highly durable products that meet global standards.

In the field of sales, Sepahan Foolad Atashgah, in addition to meeting the needs of the domestic market, has been able to expand its product exports to regional and European countries. The CEO and sales team of this company, with technical and specialized advice, help customers choose the best type of High chromium grinding balls based on the grinding conditions and the needs of the production line. Also, after-sales service and continuous support guarantee customer trust in the long term.

If you are looking to buy high chromium grinding balls with world-class quality and competitive prices, Sepahan Foolad Atashgah will be the best choice to improve productivity and reduce production costs.

Conclusion

In the cement industry, one of the most important factors for success is the correct selection of grinding media. As discussed, High chromium grinding balls have very high hardness and abrasion resistance due to their special martensitic structure and the presence of chromium carbides and can significantly improve the performance of cement mills. These features increase the useful life, reduce production stops and significantly save on operating costs. Compared to low alloy or forged steel balls, the main advantage of these products is their abrasion resistance, which allows for more stable and economical use in harsh mining environments, especially in the cement industry.

Sepahan Foolad Atashgah Company, with more than three decades of experience and the use of modern casting technologies, has been able to produce high chromium grinding balls of world quality. Paying attention to abrasion resistance in mineral castings in the design and production of these products not only helps improve the quality of cement but also increases the efficiency of the entire process. Therefore, choosing Sepahan Foolad Atashgah high-chromium pellets is a reliable solution for improving productivity and reducing production costs in the cement industry.