Forged Steel Grinding Balls: A Complete Guide

In industries such as mining, cement production, chemical processing, and power generation, forged steel grinding balls play a vital role. These balls are essential for ball mills, where raw materials are ground into fine powders. Unlike cast balls, forged steel balls are produced through a high-temperature forging process that improves toughness, hardness, and wear resistance. As a result, they last longer, perform better under stress, and reduce operating costs.

This article provides a comprehensive guide to forged steel grinding balls. We will cover their definition, production process, key characteristics, applications, innovations, challenges, and the future outlook.

What Are Forged Steel Grinding Balls?

Forged steel grinding balls are heavy-duty components designed for use in harsh grinding environments. Unlike cast balls, which are created by pouring molten metal into molds, forged balls are shaped by applying mechanical pressure to heated steel. This process removes internal porosity and produces a dense, uniform microstructure.

Industry leaders such as Alpha Grinding Media note that forged balls are superior when high abrasion resistance and impact toughness are required. They are commonly used in:

- Mining: Grinding ores like gold, copper, and iron for mineral extraction.

- Cement production: Pulverizing clinker and raw materials into fine cement powder.

- Chemical and ceramic industries: Reducing particle size for chemical compounds and ceramic products.

- Power plants: Grinding coal for efficient combustion in thermal plants.

Manufacturing Process of Forged Steel Grinding Balls

The production of forged steel grinding balls involves metallurgy, precision engineering, and strict quality control. According to Energosteel and JSW Steel, the steps include:

Click to read the article «What Makes High Chrome Balls Ideal for Cement Mills».

1. Raw Material Selection

High-quality steel billets or rods with 0.5–1.0% carbon and up to 3% chromium are selected for durability. This ensures hardness and strength under continuous grinding.

2. Heating and Forging

Steel rods are heated to about 1,000°C until pliable, then shaped into balls using hot forging or skew rolling techniques. The forging process produces a compact structure with fewer internal defects.

3. Heat Treatment

The balls are quenched and tempered to achieve hardness levels of 55–65 HRC and impact toughness above 12 J/cm². Controlled cooling and reheating balance ductility with strength.

4. Quality Testing

Standards such as IS 12658:2018 and GOST-7524-2015 require rigorous testing. Tests include hardness measurement, ball-on-anvil impact tests, and microstructure analysis.

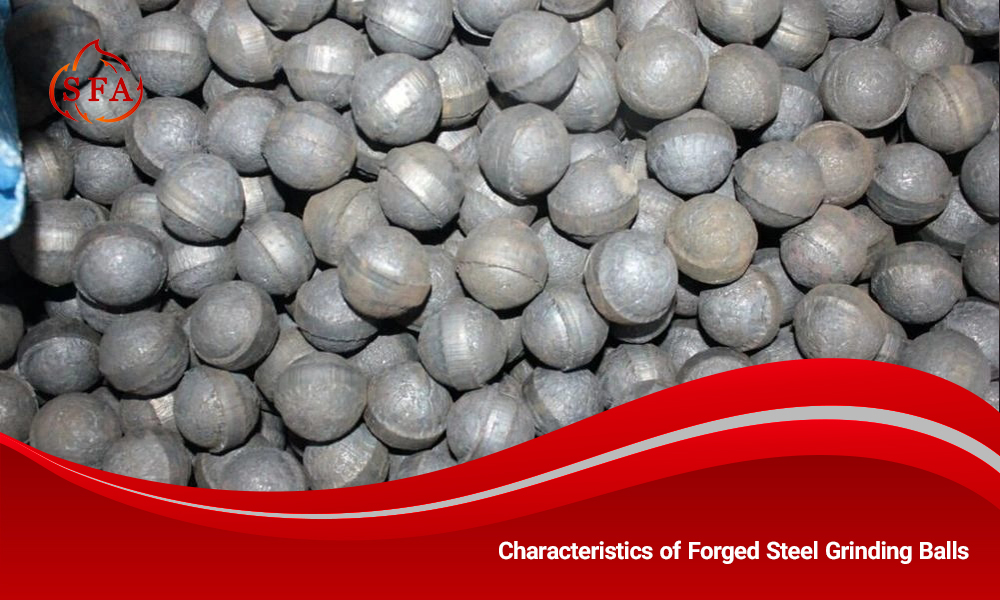

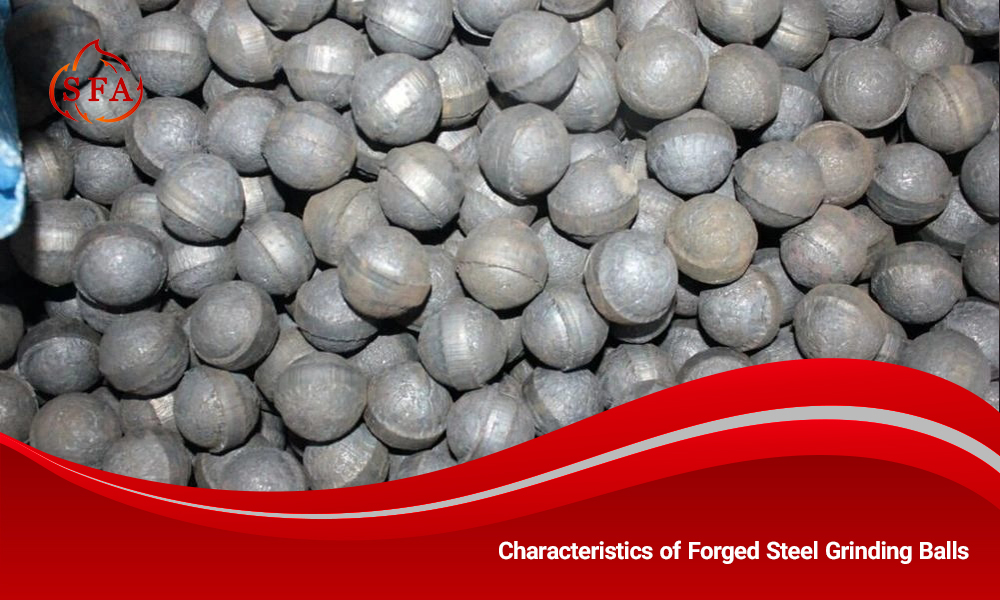

Key Characteristics of Forged Steel Grinding Balls

The forging process gives these balls several unique properties:

- High hardness (60+ HRC) → Maintains shape and resists abrasion.

- Strong toughness (≥12 J/cm²) → Withstands repeated impacts.

- Excellent wear resistance → Longer service life and lower replacement costs.

- Variety of sizes → Available in 20–150 mm diameters for different mill types.

- Uniform composition → No porosity or voids, ensuring consistent performance.

These features make forged steel balls reliable and cost-effective for industrial grinding.

Applications of Forged Steel Grinding Balls

- Mining

Used to grind ores into fine particles for mineral recovery. For example, gold and copper mines rely on forged balls to boost throughput and recovery rates. - Cement Industry

High-hardness balls grind clinker into fine cement powder, ensuring consistency and efficiency in production. - Chemical and Ceramic Processing

Used to maintain uniform particle size in chemicals and ceramics, while minimizing contamination risks. - Power Generation

In coal-fired plants, forged balls grind coal into fine powder, increasing combustion efficiency and reducing energy loss.

Innovations in Forged Steel Grinding Balls

The grinding media industry has evolved to meet modern industrial challenges. Companies like SFA and Molycop are leading innovations such as:

- Precision chemistry control → Custom alloy compositions (e.g., added chromium for specific ores).

- Advanced heat treatment → Improved quenching and tempering for longer lifespan.

- Real-time monitoring → Sensors track ball wear and mill performance, reducing energy consumption.

- Sustainable production → Recycling scrap steel and optimizing furnace energy use to reduce carbon footprint.

Challenges and Considerations

While forged steel balls offer clear advantages, there are challenges to address:

- High raw material costs → Chromium-alloy steel is expensive, raising production costs.

- Strict quality control → Maintaining consistency in mass production requires advanced testing.

- Environmental impact → Forging consumes high amounts of energy, though recycling helps mitigate effects.

- Selection issues → Choosing the wrong ball size or alloy leads to poor grinding efficiency and faster wear.

Future Outlook

The future of forged steel grinding balls looks promising. With rising demand in mining, cement, and energy sectors, research is focused on:

- Developing next-generation alloys with greater toughness and wear resistance.

- Expanding applications to new fields such as renewable energy and advanced material processing.

- Wider use of predictive maintenance and digital monitoring to optimize mill efficiency.

- Increased emphasis on eco-friendly manufacturing, including renewable energy and closed-loop recycling.

Environmental Impact of Forged Steel Grinding Balls

As industries focus more on sustainability, the environmental impact of grinding media has become a key concern. Forged steel balls, compared to cast balls, often require more energy during production due to forging and heat-treatment processes. However, their longer service life reduces the overall number of replacements needed, minimizing industrial waste. Many manufacturers, including SFA, have started implementing closed-loop recycling systems and energy-efficient furnaces to lower their carbon footprint. In the long term, this balance between durability and eco-friendly production makes forged balls a more sustainable option.

Maintenance Best Practices for Longer Service Life

Even though forged steel balls are highly durable, proper maintenance in mills ensures maximum efficiency. Some best practices include:

- Regular lubrication of mills to reduce frictional wear.

- Scheduled monitoring of ball consumption rates to detect unusual wear patterns.

- Using sensors for real-time tracking of liner and ball performance.

- Mixing ball sizes strategically to improve grinding efficiency and reduce energy use.

By following these practices, industries can extend the lifespan of grinding media and avoid costly downtime.

Global Market Demand and Industry Growth

The market for forged steel grinding balls is experiencing steady growth due to the expansion of mining, cement, and energy sectors. Reports indicate that the Asia-Pacific region holds the largest share, while the Middle East and Africa are emerging markets with increasing demand. Industries are seeking not only high-performance grinding balls but also solutions that reduce energy consumption and meet environmental regulations. With innovations in alloy design and smart monitoring, the global forged steel ball market is projected to grow significantly over the next decade, driven by rising mineral processing and cement production activities.

Conclusion

Forged steel grinding balls are the backbone of industrial grinding processes. With superior hardness, strength, and durability, these balls remain an indispensable component in the mining, cement, chemical, and power industries. Relying on modern manufacturing technologies and sustainable practices, companies such as SFA Foundry continue to supply high-performance grinding media to meet global demand.

Moreover, working with a team that leverages its knowledge and technical expertise to improve product quality can also help reduce operational costs. For example, in one project, Sepahan Foolad was able to reduce the annual operating costs of consuming plants by up to 18% simply by changing the alloy composition of the grinding balls.

Choosing the right grinding balls and maintaining them properly enables industries to achieve higher efficiency, lower costs, and longer equipment life. For expert or technical consultation, you can always contact our team of specialists, since poor choices can lead to excessive wear or ineffective grinding performance. Contact our colleagues and Commercial Manager for more advice and information.