About us

Sepahan Foolad Atashgah Foundry Industries Company (SFA)

Sepahan Foolad Atashgah Casting Industries Company was established in 1989 as a private joint stock company with the aim of casting various types of steels and cast irons. With more than three decades of continuous activity, it is now considered one of the leading casting companies.

Sepahan Foolad Atashgah Casting Industries Company has 7 furnaces with a total simultaneous melting of 20,000 kilograms in an area of 25,000 square meters, and has an annual production capacity of 25,000 tons of casting parts.

In order to continuously improve and enhance the quality of products, and to achieve maximum customer satisfaction, this company has used specialized and young personnel, as well as up-to-date equipment and technical knowledge, and has so far been able to cooperate with many reputable domestic and foreign companies in supplying various types of casting parts in various alloy groups used in various industries.

This company is capable of providing services to the iron and steel; copper; mines and related industries and the cement industry in a diverse range of alloys.

Other product groups produced by this company include casting pellets required by various industries, including mines, steel, copper, cement, production of industrial concentrates, Heplex, industrial powders, etc. In addition to supplying the casting pellets required by the aforementioned domestic industries, this company has also succeeded in exporting this product to Middle Eastern and European countries on several occasions. Sepahan Foolad Atashgah Casting Industries Company, relying on its ability and backed by organizational capital and a strategic management approach in maintaining and developing these assets, promises a bright and successful future.

Sepahan Foolad Atashgah Casting Industries Company, with more than 30 years of experience in the field of casting, is self-sufficient, utilizing young and specialized personnel and experienced managers in order to maintain its policy, utilizing quality control and quality assurance systems based on international standards, while considering organizational values, and also in order to advance the organization’s missions, utilizing advanced hardware and laboratory equipment and facilities, has been able to produce thousands of various types of parts used in industries such as mining, steel and iron, cement and copper, and deliver them with the best quality based on global standards to various domestic companies and foreign customers.

-

Quality control system

-

Quality assurance based on international standards

Just as our efforts over the past three decades have reduced the dependence of our industries in the country on other countries for the supply of various types of steel and cast iron casting products, and through the export of manufactured products, we have also reduced the number of people leaving the country, with our increasing efforts towards an integrated company management system, we have further reduced the need for various industries in the country to supply related casting parts from other countries, as well as increasing the export of our manufactured parts globally.

-

Commitment to continuous improvement

-

Export capabilities

Intra-organizational values are the introduction to achieving goals.

These values include business behavior in all areas and units of the organization, which will be the introduction to providing optimal services to customers. Other important values of Sepahan Steel Foundry Industries Atashgah are the development of a culture of environmental, health and safety, the advancement of all organizational goals based on integrated systems and processes, and attention to ever-increasing knowledge and technology.

Sepahan Foolad Atashgah Casting Industries Company, with more than 30 years of experience in the field of casting, is self-sufficient, utilizing young and specialized personnel and experienced managers in order to maintain its policy, utilizing quality control and quality assurance systems based on international standards, while considering organizational values, and also in order to advance the organization’s missions, utilizing advanced hardware and laboratory equipment and facilities, has been able to produce thousands of various types of parts used in industries such as mining, steel and iron, cement and copper, and deliver them with the best quality based on global standards to various domestic companies and foreign customers.

Just as our efforts over the past three decades have reduced the dependence of our industries in the country on other countries for the supply of various types of steel and cast iron casting products, and through the export of manufactured products, we have also reduced the number of people leaving the country, with our increasing efforts towards an integrated company management system, we have further reduced the need for various industries in the country to supply related casting parts from other countries, as well as increasing the export of our manufactured parts globally.

Intra-organizational values are the introduction to achieving goals.

These values include business behavior in all areas and units of the organization, which will be the introduction to providing optimal services to customers. Other important values of Sepahan Steel Foundry Industries Atashgah are the development of a culture of environmental, health and safety, the advancement of all organizational goals based on integrated systems and processes, and attention to ever-increasing knowledge and technology.

Quality Policy, Sepahan Foolad Atashgah Casting Industries (SFA)

Promoting a culture of continuous improvement and increasing customer satisfaction

Improving the human resources situation

Improving the state of production infrastructure

Efforts to increase market share

Improve on-time delivery status

Reducing environmental pollution and making the workplace safer

Company management team

Production Stages of Parts

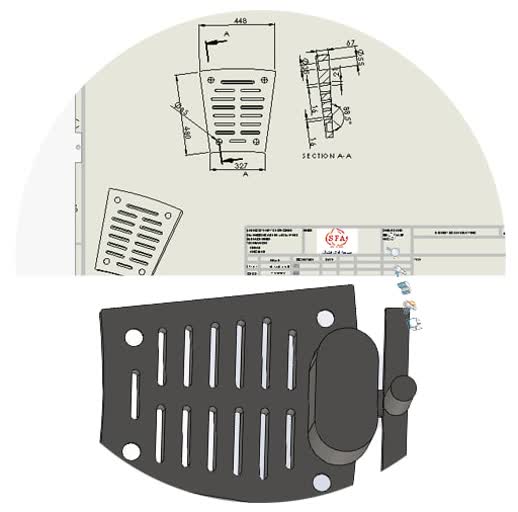

Design

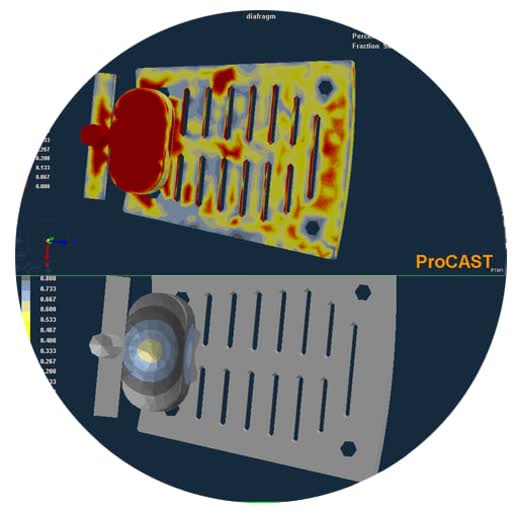

Casting Simulation

Modeling

Molding and assembly

Melting and Casting

Heat Treatment

Finishing Operations

Packaging

Stay in touch!

Sepahan Foolad Atashgah Casting Industries Company, with over 30 years of experience in the casting industry, is committed to self-sufficiency by leveraging skilled personnel and experienced managers. The company proudly serves various industries, including steel, copper, mining, cement, and their related sectors, as well as producing cast iron balls required by different industries.

Address

Isfahan – Najafabad – Najafabad Industrial Park 2 – Sanat Square – Doctor Hesabi Blvd – Sub-corner 28