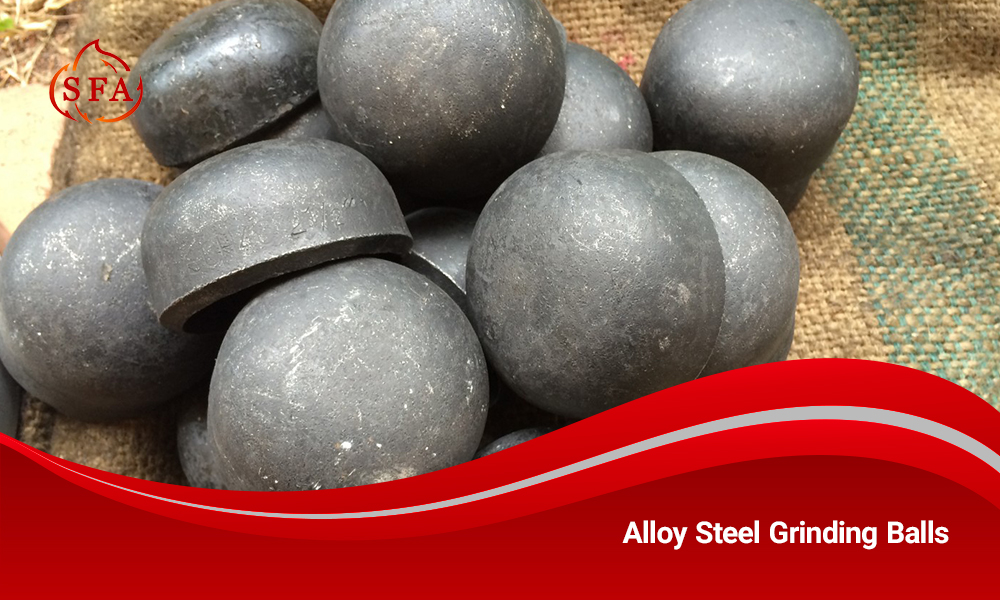

Alloy Steel Grinding Balls

The stages of material production and crushing are among the most sensitive stages in large industries, including mining, cement, and power plants. If the process of this step is not carried out properly, the entire production line will be affected, reducing production efficiency. One of the main tools used in this section is alloy steel grinding balls. Despite their simple appearance, these bullets are made with special steel compounds to withstand high pressure. The steel material of the bullets makes them highly resistant to impact and abrasion. Alloy steel grinding balls have a longer lifespan than conventional ones. Choosing the right pellet type can help reduce costs and also result in less energy consumption. In the continuation of this article from Sepahan Foolad Atashgah Foundry Industries, we will take a closer look at some tips for purchasing alloy steel balls of this product online in various industries.

Introduction and characteristics of alloy steel grinding balls

Alloy Steel Grinding Balls are spherical and highly durable pieces. They are used in various industrial mills to grind minerals, chemicals, and even cement raw materials. The composition of these bullets is usually alloy steel with elements such as chromium, manganese, nickel, and molybdenum. The presence of these elements increases the surface hardness of the bullets and at the same time makes them highly resistant to impact and abrasion. This feature has allowed them to last longer than simple steel balls and maintain stable performance even in difficult and stressful working conditions. For this reason, many mining and cement industries today consider the use of alloy steel balls as an economical and reliable choice.

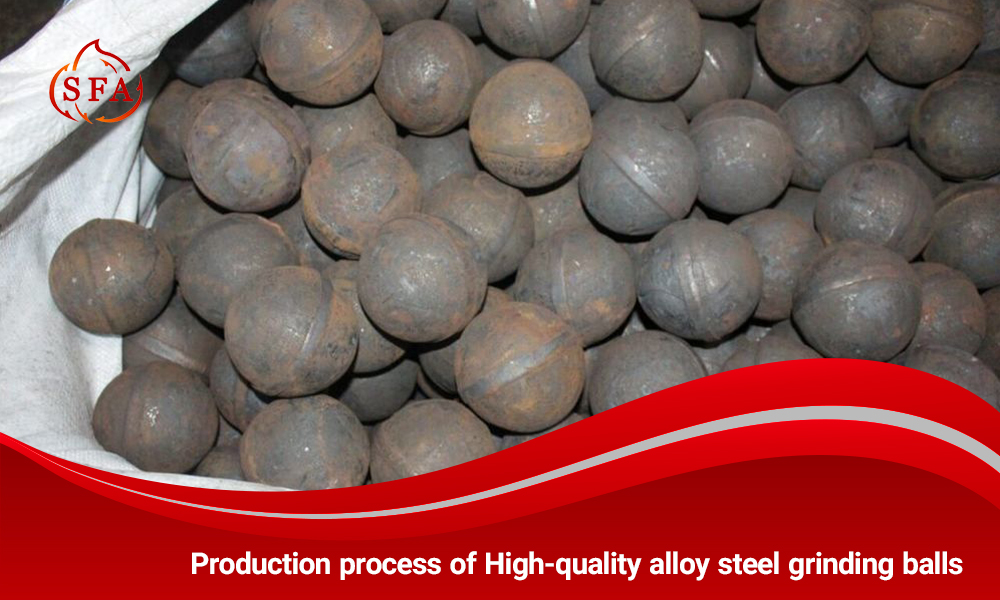

Production process of High-quality alloy steel grinding balls

You might think that producing a steel ball is simple, but the reality is that there are several specialized steps that must be taken, as follows.

- Melting and casting: Alloy steel is first melted in a furnace and then cast into special molds.

- Heat treatment: The balls are quenched and tempered to make them both hard and not brittle.

- Surface finishing: In some cases, the surface of the bullets is polished to give them greater quality and uniformity.

- Quality control: Hardness testing, impact testing, and metallographic structure examination are performed to ensure that the product meets the standard.

These steps make the pellets both hard enough to crush and resistant to breakage.

Different Types of Alloy Steel Grinding Balls

The chemical composition of the alloys causes differences in the performance and strength of the mill balls. Low-chromium balls, which contain less than two percent chromium, are suitable for low-intensity mills and are also more economical. In contrast, high-chrome bullets have greater hardness and resistance and a longer lifespan due to their high percentage of chromium. Another type of bullet is produced using special elements such as nickel and molybdenum, which are used for very specific conditions, such as high temperatures and pressures or in the petrochemical industry.

Click to read the article «Tips for Selecting the Right Ball Mill Balls for Your Plant».

Application of alloy steel balls in various industries

Alloy steel balls have many uses in various industries and their traces can be seen almost everywhere. In the cement industry, these balls are responsible for crushing clinker and raw materials, and by creating uniform grinding, they increase the quality of the final product.

In the mining industry, hard rocks such as iron ore or copper must be converted into smaller particles. Alloy bullets perform very well due to their high resistance to impact and abrasion and can handle tough jobs with ease.

Even in the chemical industry, where precision in grinding specific materials is of great importance, these balls are a reliable and efficient choice. Power plants also use them to grind coal to increase fuel efficiency and produce more efficient energy. In general, the high strength and durability of alloy steel balls allow them to maintain their optimal performance even in harsh working conditions.

Main advantages of alloy steel grinding balls

What distinguishes Alloy Steel Grinding Balls from other types is a set of technical and economic features. These bullets have a longer life, which reduces the frequency of replacements and, consequently, reduces production line downtime. In addition, high quality grinding results in lower energy consumption and a more uniform final product. Their high resistance to high pressure and temperature also helps industries to use them safely in harsh conditions. From an economic perspective, despite the higher initial price, they reduce costs in the long run.

Important points when buying alloy steel grinding balls

Most people only focus on price when choosing and purchasing high-quality alloy steel grinding balls, while the story is more complicated than that. The first thing you should definitely check is the chemical composition of the steel, because this is exactly what determines how resistant and how long the bullets will last. Experience has shown that bullets produced using the forged method are much more durable and less susceptible to wear. To go into more detail, the size and diameter of the bullet are also not without influence. Suppose your mill is designed to crush cement clinker; if the ball size is not selected correctly, not only will efficiency decrease, but you will also end up with increased energy consumption. Another important point is to pay attention to quality standards and manufacturer certificates. Finally, it is good to know that nowadays it is very easy to buy this equipment online; so that with a few simple clicks you can compare the prices of High-quality alloy steel grinding balls and choose the best option among several sellers.

Maintenance and longevity

For alloy steel balls to have the highest efficiency, it is not enough to simply purchase a quality product; attention must also be paid to maintenance and operating conditions. First of all, it’s best to check the grinder every now and then to make sure the conditions are consistent with the type of pellets you’re using. Another point is lubrication; when the right oil or lubricant is used, it reduces the friction of the bullets and also increases their lifespan. On the other hand, you should not let the balls run until they are completely worn out; timely replacement of the balls will prevent a decrease in mill efficiency and wasteful energy consumption. Where the bullets are stored is very important. When the bullets are kept in a damp or humid environment, they will rust very quickly and lose their original quality.

The future of alloy steel shot production

With the development of new technologies, manufacturers are seeking to create bullets that, in addition to being more resistant, are also more environmentally friendly. The use of nanoparticles in alloys, improving heat treatment, and designing new anti-wear coatings are among the measures that have been implemented in recent years and will shape the future of this industry. These innovations help industries both reduce their costs and produce higher quality products.

Conclusion

As seen, Alloy Steel Grinding Balls are one of the most important consumable parts in various industries. These parts play a fundamental role in crushing materials and improving production efficiency. Features such as high hardness, impact and abrasion resistance, long life, and high efficiency make these bullets a better choice compared to simpler types. On the other hand, today, the ability to purchase High-quality alloy steel grinding balls online has helped customers obtain their desired product faster, more reliably, and more economically. Ultimately, paying attention to alloy composition, production method, size, and quality standards when purchasing can ensure the success of industrial processes. Contact our colleagues and Commercial Manager for more advice and information.